Absorption Microscopy of Optical Coatings

Our novel cavity imaging technology enables to get new insight into high.end optical coatings for high power laser applications or low loss resonators.

Characterize high power, low loss optical coatings with unprecedented spatially resolved measurement of minuscule absorption and scattering. Improve quality control with ultra-fast screening for tiny defects and optimize coating parameters with a new level of insight.

Key numbers

High speed, resolution and unprecedented sensitivity at the same time.

< 1ppm Absorption

Noise floor down to 0.1ppm and few ms measurement time

» 1GW / cm² Power density

Measure with very high local powers

~1µm Resolution

Work at 4 Kelvin and below in your closed-cycle cryostat and apply magnetic fields.

10s/0.3x0.3mm² Imaging rate

High speed imaging

Features

Move your coatings and quality control to the next level

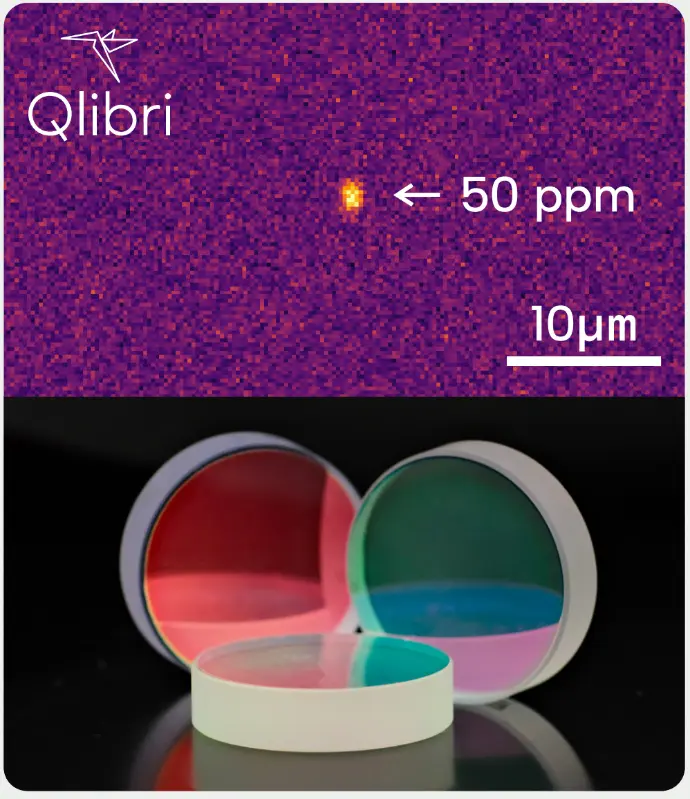

ULTRA-SENSITIVE

Sub ppm resolved absorption and scattering measurement with

micrometer resolution.

FAST

Imaging in seconds and possibility of screening whole mirrors for defects with μm resolution.

QUALITY CONTROL

Quick results in quality control lines. Detect defects early.

LOCAL FAILURE DETECTION

Detect, characterize and compare very localized and even weak local

absorbing spots, light induced damage, dirt and scratches.

ALL WAVELENGTHS

Compatible with all Wavelengths, needing only mW of laser power.

UV - MIR, 1064nm, 512nm, ...

Distinguish absorption and scattering

We can distinguish with high sensitivity absorption and scattering losses. Get insight in dominant loss channels and see spacial patterns. Optimize your HR coatings or super-polished substrates accordingly for lowest losses and higher LIDT.

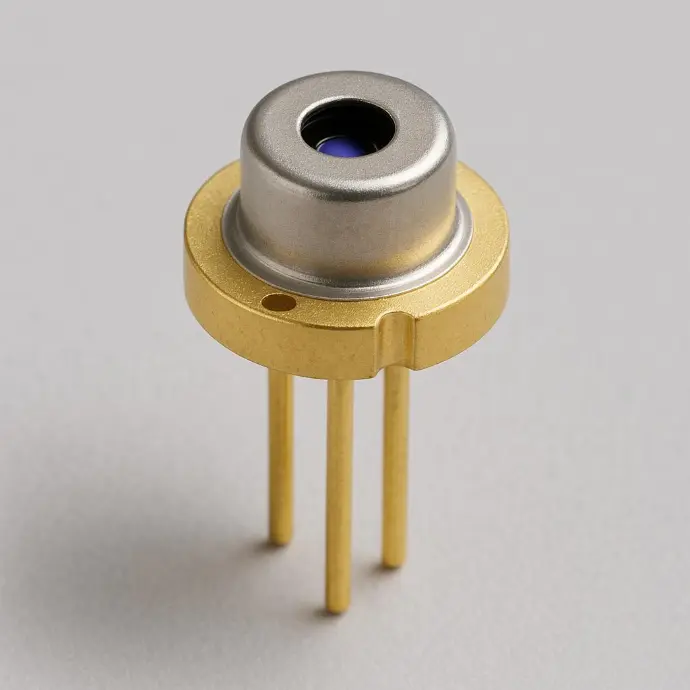

Use simple and low-maintenance Laser sources

Our technology just needs low power diode laser instead of complicated to operate high-power lasers. This simplifies inclusion in frequent processes like quality control and reduces costs for purchasing, operation and maintenance. No complex laser safety measures are required.

Spectroscopy

Get more insights into your absorbing defects by quickly collecting spectra.